Heat Treatment

We utilize fully automated SCADA-controlled furnaces for advanced heat treatment processes. These cutting-edge heat treatment processes ensure the highest quality and performance of our precision-forged components. These include:

Quenching & Tempering

Enhancing hardness and toughness through controlled heating and cooling.

ISO-Thermal Annealing

Improving material properties with a uniform heating process.

Normalizing

Refining the microstructure for improved strength and ductility.

Solution Annealing

Dissolving alloying elements for optimal hardness and flexibility.

Carburizing

Adding carbon to the surface of steel for increased wear resistance.

Carbo-Nitriding

A surface hardening process combining carbon and nitrogen for improved fatigue resistance.

Induction Hardening

Using high-frequency induction to harden specific areas of components for increased durability.

Heat Treatment

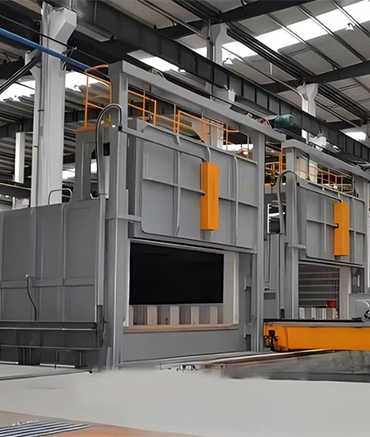

Tempering Furnace

We take pride in delivering high-quality Kirtan Precision Forged components that meet the most demanding industry standards. One of the key processes we use to enhance the mechanical properties of our forged parts is the Tempering Furnace Process. This heat treatment process is crucial for improving the strength, toughness, and overall performance of precision-forged parts. Below is an overview of the Tempering Furnace Process and how it contributes to the durability and reliability of our forged components.

We follow process like Pre-Treatment and Inspection -> Heating in the Tempering Furnace -> Holding Time -> Cooling -> Post-Tempering Inspection

Heating Furnace

We are committed to producing high-quality Kirtan Precision Forged components that meet the highest standards of durability, strength, and performance. One of the critical steps in achieving the desired mechanical properties of our forged parts is the Heating Furnace Process. This heat treatment is essential for softening the metal to make it more malleable, ensuring it is ready for the forging process, and preparing it for subsequent treatments. Below is an overview of the Heating Furnace Process and how it plays a crucial role in the overall quality of our forged components.

We follow process like Pre-Heating Preparation -> Loading the Furnace -> Heating to the Desired Temperature -> Controlled Cooling and Removal -> Inspection and Preparation for Forging